Introduction to IR Paint Curing Lamps

In the ever-evolving landscape of industrial solutions, ir paint curing lamps stand out as a modern approach to achieving superior efficiency and quality. These lamps are revolutionizing the way industries approach drying and curing processes, utilizing innovative infrared technology to deliver substantial benefits. Understanding these benefits and the specific functionalities of infrared paint curing lamps is essential for organizations aiming to enhance their operational efficacy.

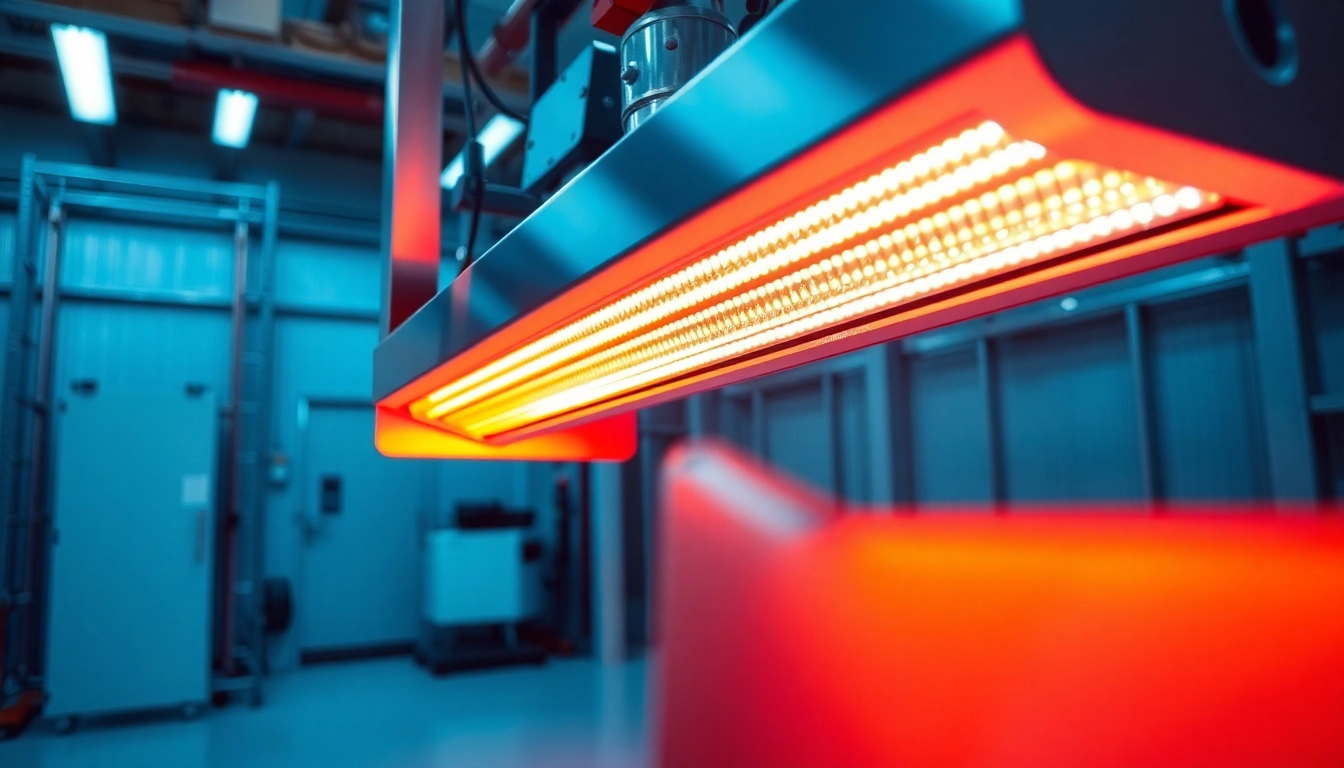

What are IR Paint Curing Lamps?

IR paint curing lamps are specialized devices designed to emit infrared radiation, which directly heats and cures paint and coatings on various surfaces. Unlike traditional drying methods that blow air onto painted surfaces, infrared lamps work by delivering heat through radiant energy, resulting in a more efficient and effective curing process. This method not only accelerates the drying time but also contributes to achieving a better finish and durability for the applied materials.

Benefits of Using Infrared Technology

The adoption of infrared technology in industries brings forth numerous benefits that are paramount in today’s competitive market. Key advantages of using infrared paint curing lamps include:

- Rapid Drying Times: IR lamps significantly reduce the drying and curing times, allowing manufacturers to increase throughput and productivity without compromising on quality.

- Energy Efficiency: With energy conversion rates up to 96%, infrared technology allows for more sustainable operation, translating to decreased energy consumption and lower operational costs.

- Improved Finishing Quality: Infrared heating provides uniform heat distribution, reducing the occurrence of imperfections in coatings and enabling a smoother finish.

- Reduced Fuel Costs: Compared to conventional heating methods, infrared lamps can lower fuel costs by 20% to 50%, providing significant financial savings for businesses.

The Role of IR Lamps in Modern Industries

Today, IR lamps play a critical role across several industries, from automotive and manufacturing to printing and woodworking. Their ability to quickly and effectively cure paints, coatings, and adhesives makes them indispensable for various applications. By implementing infrared paint curing lamps, companies can enhance their operational efficiency, ensuring they meet the demands of rapid production cycles while maintaining high standards of quality.

Types of IR Paint Curing Lamps

Infrared paint curing lamps come in various types, categorized based on the wavelength of the infrared light they emit. Understanding the differences between these types is fundamental for selecting the right lamp for specific applications.

Short-Wave IR Lamps

Short-wave infrared lamps operate at wavelengths between 1.4 to 3.0 micrometers. These lamps provide high heat outputs rapidly, making them ideal for quick curing processes. Their concentrated heat is effective in curing thick layers of paint and materials that require significant heat for activation. However, because of this intense heat, care must be taken to avoid damage to heat-sensitive substrates.

Medium-Wave IR Lamps

Medium-wave infrared lamps function at wavelengths between 3.0 to 5.0 micrometers. They strike a balance between heating speed and energy efficiency, making them versatile for various applications. These lamps are excellent for curing a wide range of coatings and are widely used in both automotive and furniture industries, where quality finishes are essential.

Long-Wave IR Lamps

Long-wave infrared lamps emit wavelengths greater than 5.0 micrometers. They produce heat that penetrates deeper into substrates, making them suitable for applications requiring gradual heating to avoid surface cracking. These lamps are often used in processes where the risk of overheating sensitive materials exists, providing a safer alternative for niche applications.

How IR Paint Curing Lamps Work

The functionality of IR paint curing lamps hinges on their unique heating mechanisms and energy efficiency. Understanding these elements can guide effective use and maintenance of these lamps.

Heating Mechanism Explained

Infrared lamps work by emitting radiant energy that is absorbed directly by the surface of the object to be cured. This heating method is efficient because it avoids intermediary heating steps, allowing for immediate heat absorption. The paint or coating then undergoes a chemical reaction, hardening in a fraction of the time required by traditional drying methods.

Energy Efficiency and Performance

One of the most compelling advantages of IR paint curing lamps is their impressive energy efficiency. By converting up to 96% of the electrical energy into usable heat, they minimize energy wastage. This not only results in cost savings but also contributes to environmental sustainability by reducing the carbon footprint of manufacturing processes.

Comparing Traditional vs. Infrared Heating

When juxtaposing traditional heating methods with infrared technology, several critical differences emerge:

- Speed: Traditional heating methods often rely on convection, which can take considerably longer to achieve the desired temperatures, whereas infrared lamps deliver immediate heat directly onto surfaces.

- Quality: Infrared curing eliminates issues such as dust and debris settling on wet paint, enabling manufacturers to achieve pristine finishes that can be difficult to attain with conventional drying techniques.

- Energy Costs: As previously mentioned, infrared heating can lower overall energy costs significantly, providing economic advantages for businesses.

Applications of IR Paint Curing Lamps

The adaptability of IR paint curing lamps has led to widespread applications across diverse sectors. Below is an overview of how these lamps are employed in various industries.

Automotive Industry Applications

In the automotive sector, IR paint curing lamps are extensively used for curing paint and finishes on vehicles. Their ability to quickly dry coats allows manufacturers to streamline production timelines, ensuring that cars move swiftly through the painting line without delay. This efficiency is crucial in maintaining competitive advantage.

Paint and Coating Businesses

Businesses specializing in paint and coatings benefit immensely from the use of infrared curing lamps. With the requirement for high-quality finishes and rapid turnaround times, these lamps provide solutions that meet both the quality and efficiency needs essential in this industry.

Industrial Manufacturing Solutions

In manufacturing environments, IR paint curing lamps are a staple, applied in various processes including curing adhesives and coatings on a range of materials. Advancements in infrared technology have resulted in equipment that can be tailored to meet specific manufacturing needs, improving both operational efficiency and product quality.

Choosing the Right IR Paint Curing Lamp

Selecting the right infrared paint curing lamp can significantly impact the efficiency and quality of operations. Various factors come into play, which need careful consideration.

Factors to Consider When Selecting IR Lamps

When contemplating the acquisition of IR paint curing lamps, businesses should evaluate:

- Type of Application: Analyze the specific needs of the application, whether it requires rapid curing or deeper penetration of heat.

- Energy Efficiency: Consider models that offer high energy efficiency ratings to maximize operational cost savings.

- Durability: Look for infrared lamps built with high-quality materials that can withstand consistent use in demanding environments.

- Customizability: Evaluate whether the option for custom fixtures and controls is available to optimize the lamps for specific production lines.

Custom Solutions and Fixtures

Huai’an Yinfrared offers a range of custom solutions for industrial heating needs. From specialized lamp designs to tailored fixtures that accommodate unique manufacturing setups, businesses can find solutions perfectly aligned with their operational requirements. Investing in custom solutions not only enhances efficiency but also boosts overall productivity.

Exploring Huai’an Yinfrared’s Offerings

With over 14 years of experience in infrared heating technology, Huai’an Yinfrared is a trusted name in the industry. The company prides itself on its patented technologies, including gold reflector and ceramic white coating, which enhance heating efficiency and target heat distribution.

Whether looking to enhance automotive drying processes, improve paint finishes, or optimize heating solutions for manufacturing facilities, Huai’an Yinfrared provides a comprehensive selection of quartz IR emitters and curing lamps tailored to meet the diverse needs of industries around the globe.