Introduction to Oxy Gas Welding Kits

Whether you’re a seasoned metalworker or a weekend DIY enthusiast, an oxy gas welding kit is an essential tool for various welding and cutting tasks. These versatile kits provide the necessary equipment to fuse metals together or cut through them with precision. As technology evolves, the demand for welding techniques that combine efficiency and effectiveness has risen, making the oxy gas welding kit a staple in both professional and hobbyist settings.

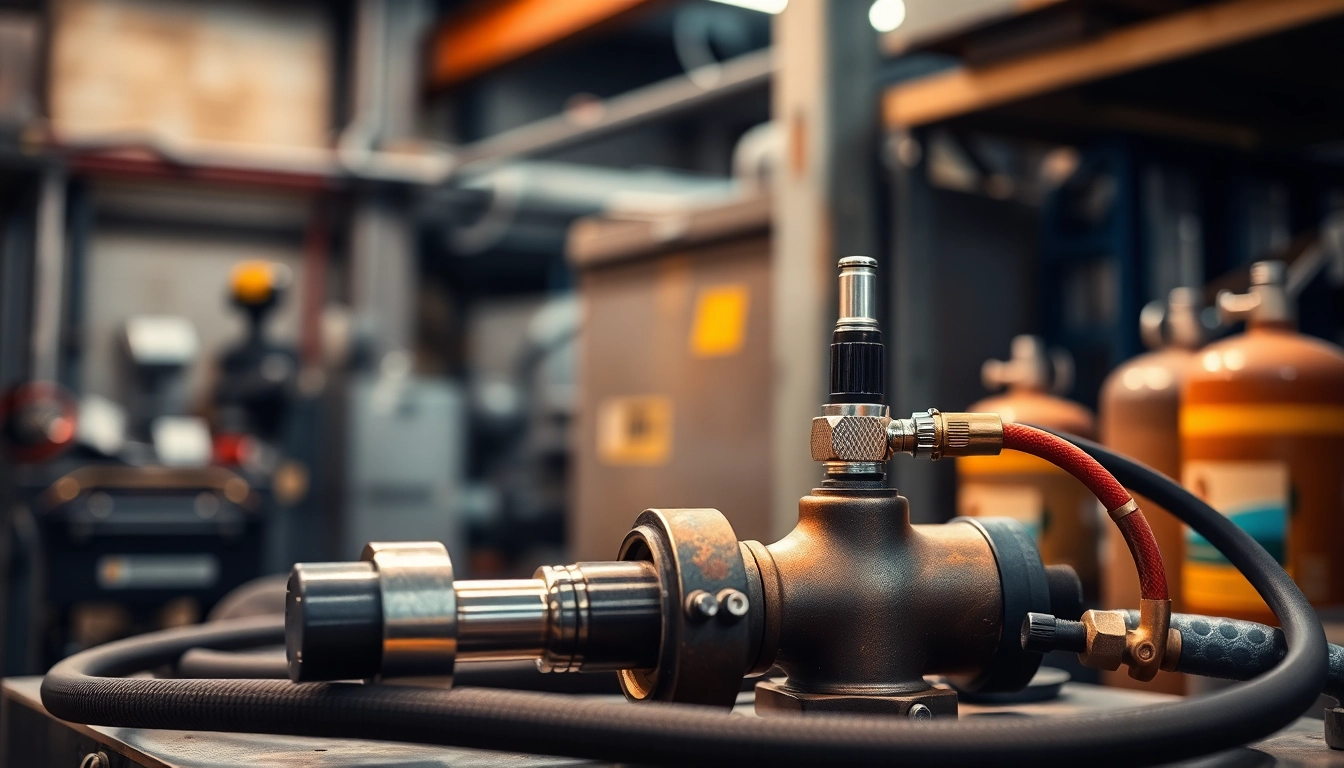

What is an Oxy Gas Welding Kit?

An oxy gas welding kit consists of essential components that work together to produce a high-temperature flame required for welding and cutting metals. The process involves a combination of oxygen and a fuel gas—often acetylene—to create a flame that reaches temperatures over 3,000 degrees Celsius (5,432 degrees Fahrenheit). The specific makeup of a typical oxy gas welding kit includes:

- Oxygen tank: A pressurized cylinder that holds oxygen used in the welding process.

- Acetylene tank: A cylinder containing acetylene gas, which acts as the fuel in the welding process.

- Regulators: Devices that control the flow of gas from the tanks to the torch, ensuring the right mix of oxygen and acetylene.

- Welding torch: The handheld device where fuel and oxygen mix and ignite, producing the flame.

- Hoses: Tubes that transport gas from the tanks to the torch.

- Welding tips: Attachments that shape the flame and determine its intensity and spread.

Key Components of an Oxy Gas Welding Kit

Understanding each component of an oxy gas welding kit is crucial for effective use:

- Oxygen Cylinder: Typically painted green, this cylinder provides oxygen at high pressure, allowing for an optimal combustion reaction.

- Acetylene Cylinder: Often painted red, this cylinder contains acetylene, which is stored dissolved in acetone to prevent it from becoming unstable under pressure.

- Regulators: These ensure that the correct pressure is maintained, which is vital for a consistent flame during welding.

- Welding Torch: The torch allows the welder to control the flame size and shape. It’s equipped with valves to regulate the gas flow.

- Connecting Hoses: Generally color-coded (one red for acetylene and another green for oxygen), these hoses are flexible and resistant to burning.

- Welding Tips: Different tips create different flame sizes and shapes, which can be adjusted based on the welding task at hand.

Common Uses of Oxy Gas Welding Kits

The versatility of oxy gas welding kits makes them suitable for various applications:

- Metal Fabrication: Essential for creating complex metal structures in construction or artistic projects.

- Automotive Repairs: Often used to weld and cut metal parts in vehicles.

- Pipe Cutting: An ideal choice for cutting pipes quickly and efficiently.

- Jewelry Making: Used by artisans for precision work.

- Maintenance and Repair: Frequently utilized in industries needing on-site welding solutions.

How to Choose the Right Oxy Gas Welding Kit

Choosing the appropriate oxy gas welding kit can significantly impact the quality of your work. Several factors must be examined before purchasing.

Factors to Consider When Selecting a Kit

When evaluating different oxy gas welding kits, consider the following:

- Intended Use: Identify whether you need the kit for professional, industrial applications or personal use. This will guide you in selecting the appropriate size and components.

- Tank Sizes: Depending on your needs, select tanks that offer the right balance between portability and longevity.

- Equipment Quality: Look for kits with durable materials. Brass regulators and high-quality hoses often ensure consistent performance.

- Brand Reputation: Research brands with solid market experience and positive customer feedback in order to invest wisely.

Comparing Different Oxy Gas Welding Kit Options

The market is flooded with options, and it’s essential to compare various kits. Some factors to measure include:

- Price: Kits can range from $100 to over $600 depending on the configuration and manufacturer.

- Included Accessories: Compare what comes with the kit, such as safety equipment (helmets, goggles) and additional welding tips.

- Ease of Use: Consider kits that have comprehensive instruction manuals or potentially additional online resources for new users.

Understanding Price Points and Value

Pricing for oxy gas welding kits can vary significantly based on several factors:

- Brand: Established brands tend to have a premium due to quality assurance.

- Kit Configuration: Basic sets cost less, while comprehensive kits with various accessories and larger tanks come at a higher price.

- Market Trends: Prices may fluctuate based on availability and demand, so it’s worthwhile to keep an eye on seasonal sales.

Setting Up Your Oxy Gas Welding Kit

Correctly setting up your oxy gas welding kit is vital to ensure both performance and safety. Follow these steps for a reliable setup.

Step-by-Step Guide to Assembly

- Gather Tools: Collect all necessary tools, including wrenches, protective goggles, gloves, and your oxy gas kit components.

- Attach Regulators: Securely attach the oxygen and acetylene regulators to their respective cylinders.

- Connect Hoses: Attach the hoses from the regulators to the torch, ensuring a tight fit. Refer to color coding—red for acetylene and green for oxygen.

- Assemble the Torch: Connect the appropriate welding tip to the torch head, ensuring it’s fastened snugly.

- Adjust Pressure: Open the cylinder valves, and adjust the regulators to your desired pressure settings.

- Test for Leaks: Before igniting, check all connections with a soapy water solution to identify any leaks.

Safety Precautions for Oxy Gas Welding

Safety should always be a top priority when using an oxy gas welding kit. Follow these precautions:

- Protective Gear: Always wear appropriate protective gear, including gloves, goggles, and flame-resistant clothing.

- Well-Ventilated Area: Ensure the workspace is adequately ventilated to prevent gas buildup.

- Avoid Flammable Materials: Keep all flammable substances away from the immediate workspace.

- Know Emergency Procedures: Familiarize yourself with what to do in case of a gas leak or fire.

Essential Tools and Accessories to Include

Beyond the basic components, consider adding the following tools and accessories to your oxy gas welding kit:

- Welding Goggles: Essential for protecting your eyes from intense light and sparks.

- Flame Retardant Clothing: Basic apparel to reduce burn risks.

- Welding Blanket: Helps protect surrounding areas from sparks and heat.

- Fire Extinguisher: Always have a suitable fire extinguisher nearby that is classified for use against gas fires.

Techniques and Best Practices for Welding

Mastering welding with your oxy gas kit requires practice and knowledge of techniques. Below are some pivotal methods and expert insights.

Basic Welding Techniques with Oxy Gas

For beginners, understanding the following basic techniques is paramount:

- Welding Positions: Learn various positions—flat, horizontal, vertical, and overhead—when working with different metals.

- Travel Speed: Maintain a consistent travel speed to achieve uniform beads and avoid overheating the material.

- Flame Adjustment: Know how to adjust the flame for neutral, oxidizing, or carburizing settings depending on the metal.

Advanced Techniques for Professionals

For professionals, mastering advanced techniques can yield unparalleled results:

- Weld Patterns: Experiment with weave patterns for added strength and aesthetics.

- Preheating Materials: Preheat thicker materials to reduce the risk of cracking.

- Use of Filler Material: Use filler rods appropriately for joint strength during welding.

Troubleshooting Common Welding Issues

Even seasoned welders encounter issues. Here’s a guide for common problems:

- Uneven Beads: Caused by inconsistent travel speed or improper flame adjustment; adjust these variables.

- Poor Fusion: Ensure the base metals are clean and free from contaminants.

- Weld Cracks: Often result from cooling too quickly; consider preheating and maintaining a steady temperature throughout the process.

Maintaining Your Oxy Gas Welding Kit

The longevity and performance of your oxy gas kit depend significantly on regular maintenance practices. Here’s how to care for your equipment effectively.

Regular Maintenance Tips for Longevity

- Inspect Periodically: Regularly check hoses and connections for wear or damage.

- Clean Components: Ensure all parts, especially welding tips and regulators, are kept clean to avoid buildup.

- Proper Storage: Store cylinders upright and chained to prevent tipping; keep them in a cool, dry place.

Identifying Wear and Tear on Components

Knowing the signs of wear can save you from costly mishaps:

- Brittle Hoses: Check for cracking or hardening of hoses.

- Regulator Damage: Look for leaks or inconsistent gas flow, which can indicate a malfunction.

- Welding Torch Tips: If they exhibit signs of excessive wear or changing shapes, it’s time to replace them.

When to Replace Parts in Your Kit

Lastly, determine when to replace various components:

- Oxygen and Acetylene Cylinders: Replace cylinders if they show corrosion or structural integrity issues.

- Regulator: If it fails to maintain consistent pressure, consider replacement.

- Welding Tips: Change these frequently as they wear out based on usage intensity.