Understanding the Basics of Oxy Gas Welding Kits

What is an Oxy Gas Welding Kit?

An oxy gas welding kit is a crucial setup for welding applications that rely on the combination of oxygen and acetylene gases. This method, known for its ability to produce intense heat, allows for effective welding, cutting, brazing, and even heating metal. The versatility of oxy gas welding makes it a popular choice among professionals and hobbyists alike, capable of joining different metal types through high-temperature fusion.

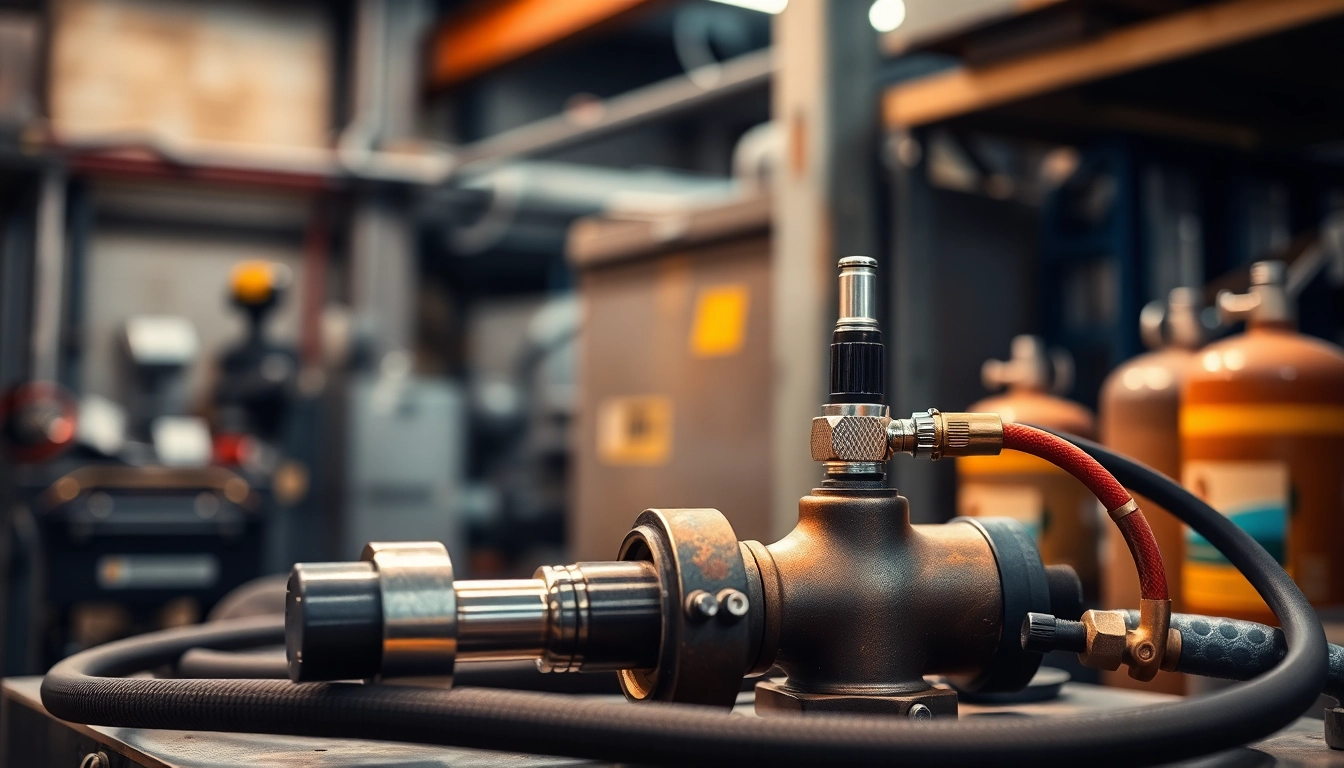

Components of an Oxy Gas Welding Kit

A standard oxy gas welding kit typically consists of several essential components:

- Oxygen Cylinder: Contains high-pressure oxygen, essential for the combustion of acetylene.

- Acetylene Cylinder: Holds the acetylene gas, the fuel used in the welding process.

- Regulators: Two crucial components that control the pressure of both gases and ensure precise flow rates to the torch.

- Welding Torch: This device mixes the two gases to create a flame, adjustable for different welding tasks by modifying the gas flow.

- Welding Hoses: Flexible tubes that transport gases from the cylinders to the torch. They are typically color-coded—red for acetylene and green for oxygen.

- Welding Goggles and Protective Gear: Safety equipment designed to protect the eyes and skin from harmful UV rays and sparks produced during the welding process.

Applications for Oxy Gas Welding

The applications of oxy gas welding are extensive and varied, making it a valuable skill in multiple fields:

- Metal Fabrication: Used in crafting and repairing metal products across several industries, including automotive and aerospace.

- Artistic Metalworking: Artists and sculptors utilize oxy welding for creating intricate designs and sculptures.

- HVAC Repair: Commonly employed in the installation and maintenance of heating and air conditioning systems.

- Pipelines and Structural Welding: Essential for constructing pipelines where high-strength joints are required.

Choosing the Right Oxy Gas Welding Kit for Your Needs

Factors to Consider When Buying

Selecting the right oxy gas welding kit involves evaluating various factors tailored to your specific needs:

- Intended Use: Whether it’s for heavy industrial use, light repairs, or artistic projects will influence the type of kit required.

- Capacity and Size: Smaller kits are portable and suitable for home use, while larger setups are designed for industrial applications.

- Brand and Durability: Opt for reputable brands known for quality and safety. Reading user reviews can also inform your choice.

- Budget: Determine how much you are willing to spend. Keep in mind that investing in a quality kit often pays off in reliability and performance.

Comparative Analysis of Popular Brands

When considering brands, a few stand out in the market:

- Harris Welding Supplies: Known for their resilience and quality. Their kits often include both welding and cutting capabilities, making them versatile.

- Victor Technologies: A popular choice for professionals due to their extensive range of accessories and durable construction.

- Unimig: Offers a balance between affordability and performance, making them ideal for both beginners and experienced welders.

Budgeting for Your Oxy Gas Welding Kit

Understanding the costs involved is crucial for effective budgeting. A basic oxy gas welding kit can start at around $100, while more comprehensive professional kits can exceed $1000. Allocate funds not just for the kit itself but also for necessary accessories, safety gear, and ongoing maintenance expenses.

Safety Tips for Using Oxy Gas Welding Kits

Protective Gear and Equipment

Safety should always be a top priority when handling oxy gas welding equipment. Essential protective gear includes:

- Welding Goggles: To protect the eyes from bright flames and harmful UV light.

- Gloves: Heat-resistant gloves guard against burns and cuts.

- Protective Clothing: Flame-resistant clothing helps protect against sparks and heat.

- Respirator: In poorly ventilated areas, a respirator ensures safety from harmful fumes.

Best Practices for Setup and Operation

To operate your oxy gas welding kit safely:

- Always check for leaks before using your equipment.

- Store gas cylinders upright in a secure location, away from sources of heat.

- Consult the user manual for specific instructions regarding operation and maintenance.

- Never use oils or grease on cylinder valves; they can create an explosive reaction.

Common Safety Hazards to Avoid

Avoiding common hazards can make the welding process safer:

- Flammable Materials: Keep your workspace clear of flammable liquids and materials to prevent ignition.

- Improper Ventilation: Always work in a well-ventilated area to avoid harmful gas accumulation.

- Neglecting Equipment Checks: Regularly inspect your kit for wear and tear to prevent accidents.

Maintenance and Care for Your Oxy Gas Welding Kit

Routine Inspection and Cleaning Tips

Regular maintenance extends the life of your oxy gas welding kit:

- Inspect hoses for cracks or leaks before each use.

- Clean the torch tip regularly to prevent clogging from soot or debris.

- Check cylinder valves for proper functionality and cleanliness.

Storage Solutions for Longevity

Proper storage is vital for the safety and longevity of your equipment:

- Store cylinders in an upright position, secured to prevent tipping.

- Keep your welding kit in a dry, protected area away from direct sunlight.

- Consider investing in a dedicated storage container for small parts and accessories.

When to Replace Parts

Knowing when to replace parts can prevent failures during crucial tasks:

- Replace hoses that show signs of wear, such as cracking or abrasions.

- Regulators should be replaced if they show inconsistent pressure readings or leaks.

- Always replace the torch tip if it has been damaged or clogged beyond cleaning.

Advanced Techniques in Oxy Gas Welding

Creative Projects Using Oxy Gas Welding

Oxy gas welding is not just for industrial applications but also lends itself beautifully to creative projects:

- Metal Sculptures: Many artists create stunning pieces by twisting, bending, and welding metal scraps.

- Furniture Design: Unique, custom furniture can be crafted through careful welding techniques.

- Restorations: Vintage car restoration often utilizes oxy gas welding for intricate repairs.

Innovative Applications in Professional Settings

Professional industries leverage the power of oxy gas welding to enhance their capabilities:

- Manufacturing: In large-scale production, oxy welding is used for assembly and repairs of heavy machinery.

- Shipbuilding: The marine industry relies on oxy welding for both new builds and maintenance.

- Artisan Work: Skilled craftsmen are using oxy welding to create custom metal designs that blend artistry and functionality.

Future Trends in Oxy Gas Welding Technology

The field of oxy gas welding is continually evolving, influenced by technological advancements:

- Automation: Companies are beginning to integrate automated torch systems for increased precision and efficiency.

- Improved Safety Features: Developments in safety equipment are leading to better protection for welders, including advanced breathing apparatus and flame-retardant gear.

- Hybrid Techniques: Combining oxy gas welding with other techniques such as MIG or TIG welding for enhanced versatility in fabrication.